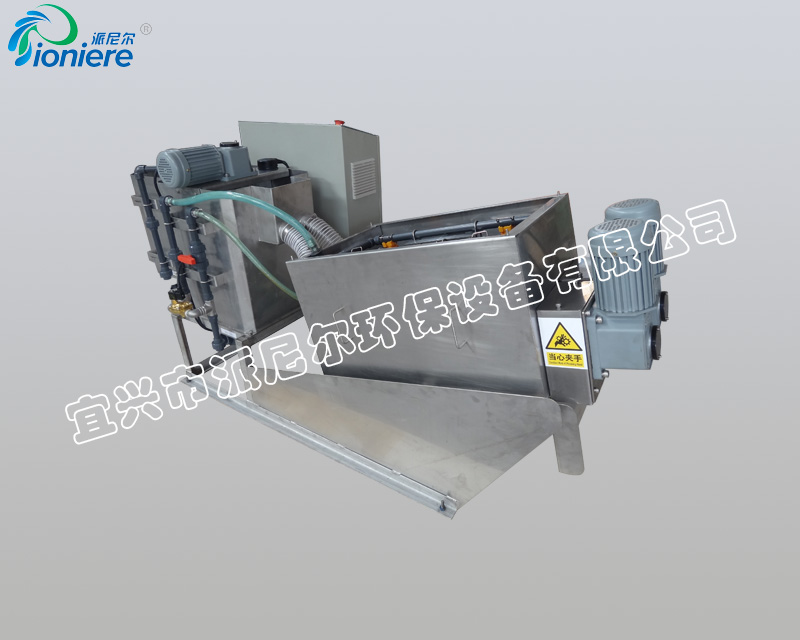

Screw Type Sludge Dewatering Equipment

When dewatering unit is working sludge is pushed forward to the discharge outlet by pressure from screw blades.

Screw Type Sludge Dewatering Equipment

When dewatering unit is working sludge is pushed forward to the discharge outlet by pressure from screw blades.

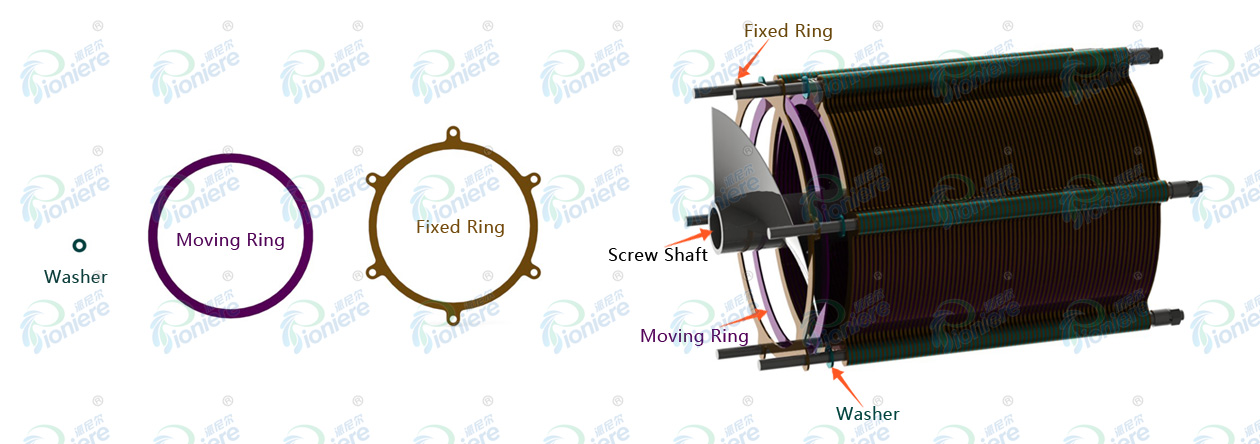

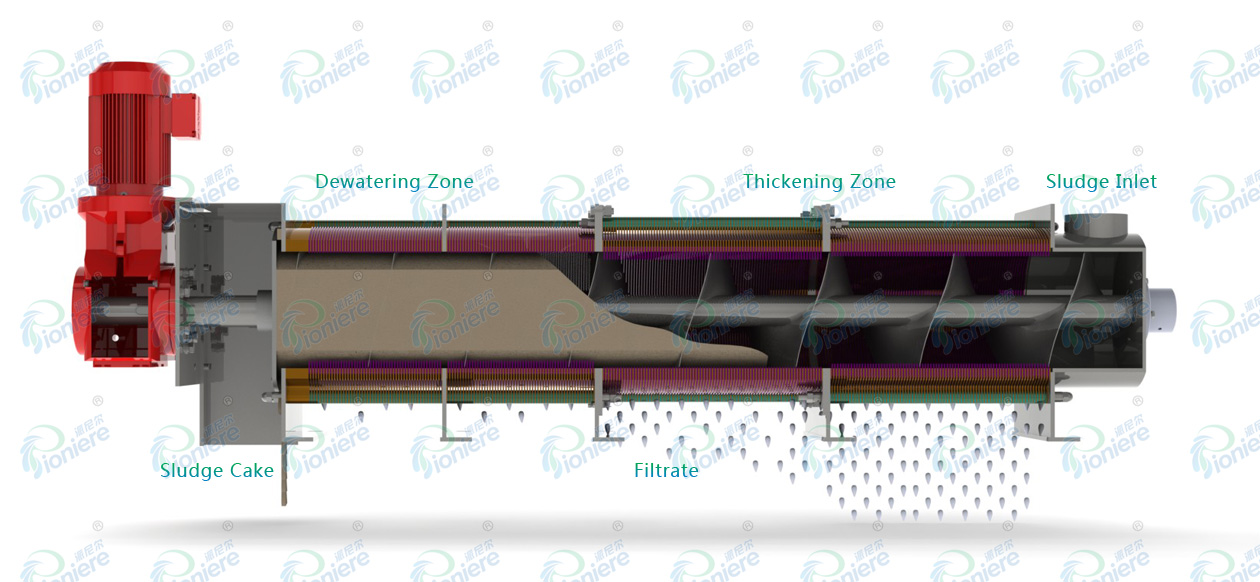

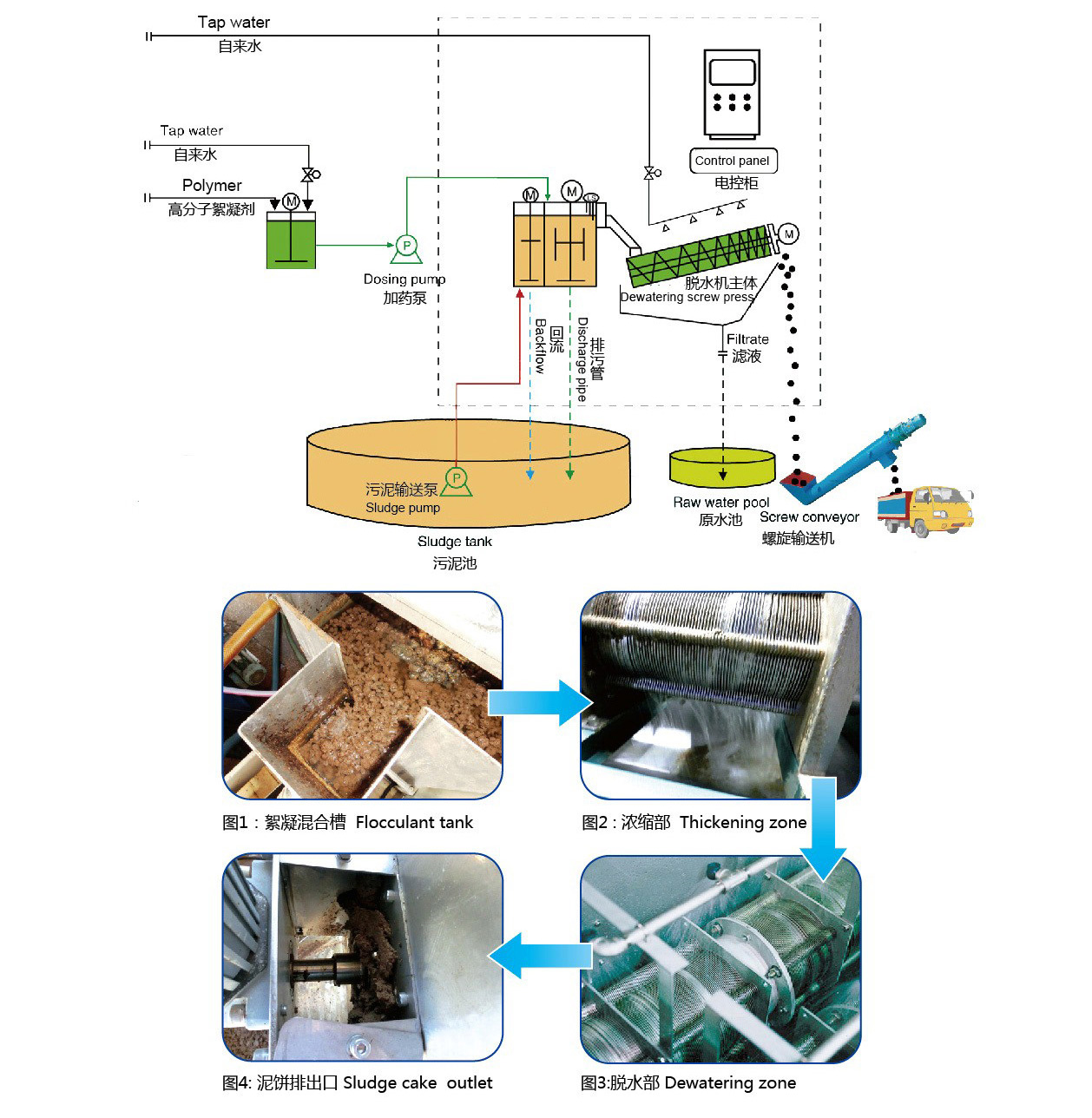

When dewatering unit is working, sludge is pushed forward to the discharge outlet by pressure from screw blades. The whole filter cylinder is composed of fixed rings moving rings and a screw shaft. The First two sections are thickening zone the last two sections are dewatering zone. The space between screw blades gets more and more narrower which means the inner pressure gradually gets bigger. Then liquid is squeezed out from the sludge and leak from the small gaps between rings. As the moving rings are pushed ups and downs by screw blade the whole cylinder is well protected from blockage. After dewatering process the sludge cake goes out from discharge outlet.

The filter cylinder is composed of fixed rings moving rings and screw shaft. Each moving ring locates between fixed rings. Moving rings diameter is slightly smaller than outer diameter of the screw. And its thickness is a little narrower than the space between fixed rings. And helical blades spinning makes moving rings move ups and downs continuously. As a result it keep the equipment working without clogging. With the gravity effect sludge get thickened and dewatered in both zones. And liquid is squeezed from sludge under the pressure from backpressure plate.

Low operating cost: 40% of Belt Press 20% of Decanter Centrifugal.

Low operating cost: 40% of Belt Press 20% of Decanter Centrifugal.

Power-Saving: 5% of Decanter Centrifugal.

Power-Saving: 5% of Decanter Centrifugal.

Water-Saving: 0.1% of Belt Press.

Water-Saving: 0.1% of Belt Press.

Polymer-Saving: save 60% polymer in average.

Polymer-Saving: save 60% polymer in average.

Compact Design: Save space and save 60% construction cost.

Compact Design: Save space and save 60% construction cost.

Non-Clogging Design: handle oily sludge easily.

Non-Clogging Design: handle oily sludge easily.

◆ Widely applied in municipal sewage industries of food beverage chemical leather petro-refining printing&dyeing papermaking pharmacy.

◆ Simple technological process high-efficiency & energy-saving low system investment.

◆ Pre-programmed system makes operation easy and convenient.

◆ Pre-programmed system makes operation easy and convenient.

|

Model |

Dry solid Output |

Dimension(mm) |

Power consumption (kw) |

Rinsing water consumption |

N.W. (kg) |

|||

|

Low concentration |

High concentration |

L |

W |

H |

||||

|

XF 101 |

~3 |

~5 |

1816 |

756 |

1040 |

0.2 |

24 |

190 |

|

XF 131 |

~6 |

~10 |

1969 |

756 |

1040 |

0.2 |

24 |

205 |

|

XF 132 |

~12 |

~20 |

2069 |

910 |

1040 |

0.3 |

48 |

275 |

|

XF 202 |

~18 |

~30 |

2500 |

935 |

1270 |

0.8 |

64 |

470 |

|

XF 301 |

~30 |

~50 |

3255 |

985 |

1600 |

0.8 |

40 |

820 |

|

XF 302 |

~60 |

~100 |

3455 |

1295 |

1600 |

1.2 |

80 |

1350 |

|

XF 303 |

~90 |

~150 |

3605 |

1690 |

1600 |

1.95 |

120 |

1820 |

|

XF 352 |

~120 |

~200 |

4140 |

1550 |

2250 |

3.75 |

144 |

2450 |

|

XF 353 |

~180 |

~300 |

4420 |

2100 |

2250 |

6.0 |

216 |

3350 |

|

XF 403 |

~270 |

~450 |

5150 |

2350 |

2550 |

6.0 |

316 |

4350 |

|

XF 404 |

~360 |

~600 |

5350 |

2850 |

2550 |

7.87 |

450 |

5250 |

| Item / Type |

Screw Press |

Belt Press |

Frame Press |

Centrifuge |

|

Product Photo |

|

|

|

|

|

Low concentration wastewater |

YES |

NO |

NO |

NO |

|

24h automatic operation |

YES |

NO |

NO |

NO |

|

Sludge thickening tank |

NO NEED |

NEED |

NEED |

NEED |

|

Sludge storage tank |

NO NEED |

NEED |

NEED |

NEED |

|

Power consumption |

Very little |

Much |

Medium |

Maximum |

|

Rinsing water consumption |

Very little |

Maximum |

Much |

Little |

|

Noise & Vibration. |

Small |

Big |

Small |

Quite Big |

|

Sludge Viscous |

Low |

High |

High |

Medium |

HOTLINE:(86)-510-88568099

HOTLINE:(86)-510-88568099 CHINESE

CHINESE